|

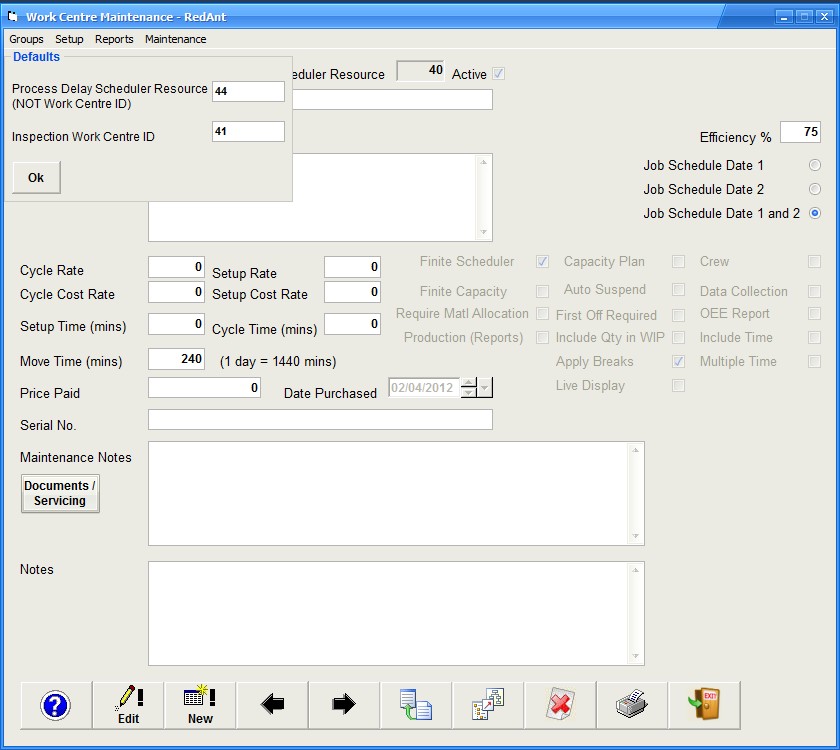

Defaults

|   |

Process Delay is a way of adding a delay time to an operation in such a way that it does not stop the next operation from starting on a work centre. We creat a special work centre called 'Process Delay' to be used as a dumpong ground for these small pockets of time. This work centre must have the finite capacity check removed so it can handle infinite time entries all at the same time. The delay time is entered in to the move time column when creating a manufacturing plan. Here it is not treated as chargeable time and can be dealt with appropriately. Every work centre added to the system is given a unique system id number called a resource number. This can be found next to the work centre ID. This number is used for the scheduler resource no. as shown below.

Inspection Work Centre ID is used when assigning a first off requirement to the inspection department. The inspection work centre will also have a resource id which will be entered here. See data collection for further details