|

Subcontract Tab

|   |

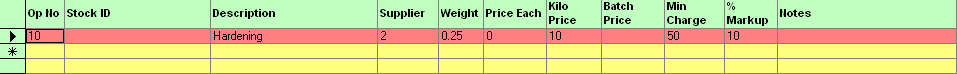

Where an item requires external work .e.g. heat treatment or plating to be carried out by a third party supplier then this section has been specifically designed to do just that. The Op No field is used to tell the system which operation this subcontract item refers to. You may have several different subcontract items for any one drawing and this allows us to tie each one up with an operation. Leave this empty for the tutorial. The Stock ID field can be used to select from a list of special stock records created specifically for subcontract work. As with materials mentioned earlier, by using stock id’s then this can save time and speed up data entry. Let us leave the stock id empty and enter ‘hardening’ in the description field. Select a supplier from the dropdown list and then move on to the weight field.

Depending on how your supplier is charging you for this service will depend on what combination of fields you fill in next. If the supplier is charging on a weight basis then fill in the item weight and the kilo price. If they are charging on an individual basis then fill in the price each field. If it’s a price for the whole lot then use batch price. Finally the minimum charge field can be used with any of the of other pricing options so that if the total of the items does not reach the minimum charge then the system will automatically cost in the minimum charge value to the estimated price. Percentage mark-up is as per the material section and is added into the estimated price. Again the notes field is used for any important information you need to keep. For our example then enter a weight of 0.25, a price per kilo of 10.00 and a minimum charge of 50 with a 10% mark-up.

Next - Misc. /Tools Tab