|

Work Centres

|   |

From the Main Menu select Modules >> Maintenance >> Work Centres

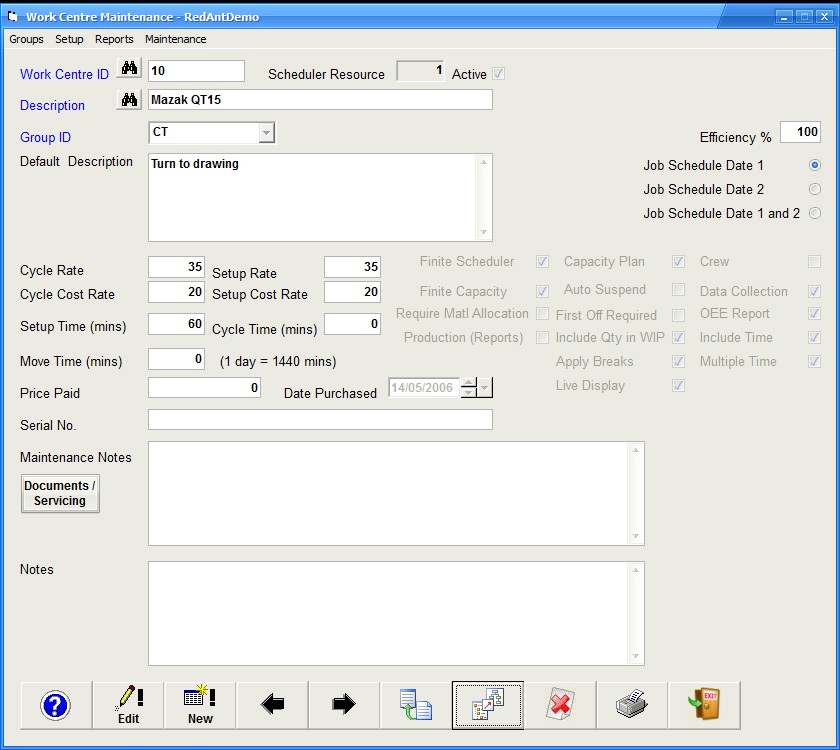

Work Centres can be defined as areas of manufacturing and they do not have to be a physical machine. The following screen shot show a typical example of a work centre. Other examples are:

Bridgeport Mill

Inspection

Subcontract Hardening

Subcontract Plating

Grinding Centre

Welding

etc

Each work centre must be given a unique ID up to 10 alpha numeric digits in length. It is advisable to make shop floor operators aware of these ID's by making them visible where possible on actual machines.

Examples of ID's could be:

CM1 CNC Milling machine 1

CM2 CNC Milling machine 2

CT1 CNC Turning Machine 1

CT2 CNC Turning Machine 2

IN Inspection

W1 Weld1

W2 Weld2

FAB1 Fabricate 1

SCH Subcontract Harden

SCA Subcontract Anodise

ASSY Assembly

Each work centre must belong to a valid Group (see group setup) for planning and scheduling purposes.

Field Definitions

Work Centre ID

A unique code which identifies each individual machine or manufacturing process

Scheduler Resource

This is a non-editable unique reference generated by the system for the work centre. It is used internally by various functions of the system

Active

If this work centre is no longer required, has been sold or scrapped then uncheck the field. It will no longer be available within the system but has to remain as a record for historical purposes

Description

A description of the workcentre including model where applicable

Group ID

The Group which the work centre belongs to

Default Description

This is the description that will be initially used when using this work centre is selected for use in a process plan. It may be something simple like 'Mill To Drawing' or Assemble Parts' or 'Subcontact Heat Treatment. This description can always be changed by the user at a later date.

Cycle Rate

The rate per hour that you charge the customer for cycle time

Cycle Cost Rate

The rate per hour the work centre is costing. This is not something that can be estimated and needs input from your accountants based on current andpredicyed expenditue as well as overhead costs

Setup Rate

The rate per hour that you charge the customer for setting the work centre

Setup Cost Rate

As per Cycle cost rate above

Setup Time

A default time in minutes that will be applied each time the work centre is used in a new plan. This can be changed at any point

Cycle Time

As per Setup Time above but for cycle time

Move Time

A default time in minutes applied to the process movement time. This is useful for subcontract work centres when you want to apply for example 5 days turnaround for parts. This can be changed at any time to reflect the suppliers current turnaround and then apploed to scheduling.

Price Paid

The price paid for the work centre (information only)

Date Purchased

Date when purchase (information only)

Serial No.

Serial no. of the work centre (information only)

Maintenance Notes

Any work centre maintenance notes (reference only)

Notes

Any general notes (reference only)

Efficiency

this value (default 100%) defines how efficient a work centre is when it comes to capacity planning and scheduling. No work centre is going to be 100% efficient so using this entry we can fine tune the throughput of work to give more accurate schedules. There a numerous factors effecting a work centre's efficiency for example, if the work centre is on a long running job and it is bar or pallet fed it can be very efficient whereas a single employee running 3 work centes at the same time is not. We encourage all new users to set this somewhere in the region between 60 and 75%. Once we have captured data from the system spanning several months we can fine tune this figure better.

Job Schedule Date

There are 3 options available here which are selected using the radio button. Every Job order can have 2 additional scheduling date fields applied. These are Material Due Date and Available Start Date. The scheduler has the ability to use 1 or both of these dates and apply the results to calculate the final completion date for the job. By selecting Date 1, the scheduler will only check for when material is due for delivery and schedule accordigly. If selecting only Date 2, the scheduler will not consider scheduling until the available date has passed. Selecting the Date 1 and Date 2 option, the scheduler will take both dates in to account. See Finite Scheduler for more details

Finite Scheduler

use this work centre in finite scheduling calculation

Capacity Plan

use this work centre in capacity planning calculation - N.B. If this work centre is subcontract related, i.e. the work is carried out externally to the company then make sure this is unchecked

Crew

If this work centre requires a 'Crew' of employees to operate then check this box. It will save a lot of time when initiating work from the shop floor

Finite Capacity

Does this work centre have a fixed (finite) capacity per day? In other words can it cope with more than one job at a time. Invariably only subcontract work centres can do this so for anything internal this should be left checked

Auto Suspend

If this is unchecked then the work centre will carry on running when a user clocks out

Data Collection

Make this work centre available to employees to use on the shop floor

Require Material Allocation

If checked then an employee will not be able to start work on the job until material has been allocated to it

First Off Required

If this is checked, any user selecting this work centre as part of a plan will invoke a first off requirement. This can be removed at planning stage

OEE Reporting

Include this work centre in Optimum Equipment Efficiency reports

Production Reports

Include this work centre in production reports

Include Qty in WIP

When employees enter quantities completed for this work centre, are these to be included in work in progress calculation

Include Time

If unchecked then any estimated time for this work centre will not be included in the overall estimate

Apply Breaks

If unchecked, break time will not effect the running of the work centre. The system would then assume that if an employee had a lunch break the work centre would continue to accumulate time

Multiple Time

Allow multiple jobs to be booked to the work centre at the same time. Check the box to allow

Live Display

Show this work centre in the shop floor live display application